Anodized Finishing: Aluminum Anodizing That You Need to Know

Anodized aluminum can improve corrosion resistance, increase durability and improve adhesion for paints and adhesives. Aluminum parts can be effectively given better mechanical qualities or aesthetic improvements by anodizing. Even though the procedure for anodizing aluminum is pretty straightforward, many individuals are unaware of it.

Continue reading to find out more about anodizing aluminum process in a manufacturing setting.

Aluminum Anodization Overview

Anodization, also known as the anodizing process, is a method that enhances the surface of aluminum by forming a thicker and more uniform oxide layer through an electrolytic procedure. This electrochemical process results in an aluminum oxide surface boasting several advantageous attributes, including: Corrosion resistance, Aesthetic appeal, Wear resistance, Improved adherence for paint or adhesives, Enhanced lubricity, Improved plating adhesion.

We primarily delves into the anodization of aluminum. Nonetheless, it’s worth noting that other metals, such as magnesium, titanium, and aluminum alloys, can also undergo anodization. Various finishes can be achieved in anodized aluminum, including clear anodized aluminum, black anodized aluminum, and hard anodized aluminum. There are also widely recognized anodizing types, denoted as Type I, Type II, and Type III.

In many industries, the anodizing process is governed by the military specification MIL-PRF-8625 (which has superseded MIL-A-8625). This specification outlines details such as anodizing line design and anodizing patterns. Throughout this article, we will reference it on several occasions. Nevertheless, it is advisable to verify your specific anodizing requirements before finalizing your design.

Advantages of Anodization

The anodizing process replaces the natural aluminum oxide layer with a new one, enhancing the durability of the component, paint adhesion, overall appearance, and corrosion resistance. It also results in a chemically resistant coating that can withstand harsh cleaning agents. In its essence, anodization involves immersing the base metal in an acid bath and applying an electrical current to create the anodic layer. In simpler terms, it entails creating a controlled and durable aluminum oxide layer on the component’s surface, as opposed to relying on the thin oxide layer naturally present on bare aluminum. This process is akin to other conversion coating methods, such as bluing, Parkerizing, and passivating, which are used to enhance corrosion resistance and surface hardness.

Common Applications of Anodized Aluminum Components

Anodized aluminum finds widespread utility in a multitude of applications, with one of its primary uses being in enhancing aesthetics through the option of dyeing components in a diverse array of colors.

Anodized Heat Sinks: Anodized coatings serve to significantly enhance the efficiency of heat sinks. By improving surface emissivity, anodization increases radiation heat transfer by an order of magnitude when compared to untreated aluminum.

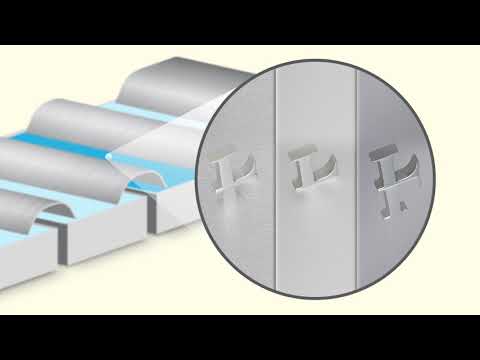

High-Quality Anodic Layers: Certain components feature exceptionally high-quality anodic layers. Noteworthy are the attractive laser-etched logos that stand out against the rest of the component. It is a common practice to etch through the anodic layer rather than printing on the surface of a part. This not only augments the durability of the logo but also reduces costs and process steps.

Outdoor Signage: Anodized aluminum sheets prove excellent for outdoor signage due to their lightweight nature, corrosion resistance, and superior durability when compared to painted alternatives. The anodized surface readily accommodates screen printing and the application of reflective materials.

The above examples, though diverse, merely scratch the surface of the myriad potential applications for anodized aluminum. For a more in-depth exploration of possibilities and additional illustrations, we welcome you to engage in further discussions with us.

Available Types of Anodizing Processes for Aluminum

In accordance with military specification MIL-PRF-8625, there are three primary types of anodizing processes:

Type I

Type I and IB: Chromic Acid Anodizing

Type IC: Non-Chromic Acid Anodizing (utilized as a substitute for Type I and IB)

Type II

Type II: Conventional coating achieved through a sulfuric acid bath

Type IIB: Non-chromate alternative for Type I and IB coatings

Type III

Type III: Hard Anodize

Each type of anodization imparts distinct functional and aesthetic characteristics:

Types I, IB, and II primarily serve for corrosion resistance, abrasion resistance, and preparation for paint application. In fatigue-critical applications, Types I and IB are favored for their thinner, more flexible coatings, commonly used in the aerospace industry for highly fatigued structural components.

Types IC and IIB come into play when a non-chromate alternative is sought, often due to environmental regulations. They serve as environmentally friendly substitutes for Types I and IB, which contain hexavalent chromium.

Type III is predominantly employed to bolster abrasion and wear resistance. This thicker coating surpasses other types in terms of resilience against abrasion and wear. However, it may reduce the fatigue life of the component. Type III anodization is frequently utilized in firearm components, gears, valves, and parts involved in relative sliding motion.

Irrespective of the type, anodization consistently enhances the adhesion of paints and various bonding agents in comparison to untreated aluminum. Furthermore, some parts may undergo dyeing, sealing, or treatment with supplementary materials, such as dry film lubricant. In cases where dyeing is employed, it results in a Class II designation, while undyed parts are classified as Class I per MIL-PRF-8625 specifications.

Key Considerations for Anodized Aluminum

When preparing for the anodization of aluminum components, there are several crucial factors to take into account. These elements play a vital role in achieving the desired results and ensuring the success of the anodization process. Here’s what you need to consider:

Dimensions

Anodization leads to dimensional changes in aluminum components. As the anodic layer forms, the surfaces tend to “grow,” resulting in an increase in the outer diameters and a reduction in hole sizes.

The extent of dimensional growth is estimated at roughly 50% of the total thickness of the anodic layer, though this can vary based on the alloy and process controls.

Different Coating Type corresponds to different Thickness Range, as below:

l, IB, IC and IIB: 0.00002 to.00070 inch (0.00051 to 0.01778 mm)

II: 0.00007 to0.0010 inch (0.001778 to 0.0254 mm)

III: 0.0005 to0.0045 inch (0.0127 to 0.1143 mm)

For high-precision features, controlling growth may require masking or post-processing adjustments, such as lapping or honing, at an additional cost.

Consider minimum corner radii, especially for Type III coatings, as sharp corners may not anodize well. This is especially true for Type III coatings, where MIL-PRF-8625 recommends the following minimum corner radii for a given Type III thickness.

Different Anodic LayerThickness corresponds to different Edge or Corner Radii, as below:

0.001 in(0.025 mm): 0.031 inch (0.794 mm)

0.002 in(0.051 mm): 0.063 inch (1.588 mm)

0.003 in(0.076 mm): 0.094 inch (2.381 mm)

0.004 in(0.102 mm): 0.125 inch (3.175 mm)

(P.S. the left stands for Anodic Layer Thickness, while the right stands for Edge or Corner Radii)

Wear Resistance

Anodization enhances the hardness of the component’s surface, leading to increased wear resistance.

It’s generally not necessary to specify the hardness of the coating itself because the interaction between the softer base metal and the hard anodic layer is complex.

Instead, consider abrasion resistance tests, as outlined in MIL-PRF-8625, to evaluate the coating’s performance.

Adding Color with Dyes

Anodized coatings are often dyed for various reasons, including aesthetics, reduction of stray light in optical systems, and part contrast or identification in assemblies.

Discuss the coloring process with your anodizing shop. Various coloring methods are available, each with its unique characteristics and limitations.

Achieving consistent color matching, especially for assemblies with multiple anodized parts, can be challenging. Consider fading and dye responsiveness when selecting colors.

Conductivity

Anodic layers are insulators, even if the base metal is conductive. If grounding is required, apply a clear chemical conversion coating and mask relevant areas.

Conductivity testing with a digital multimeter can help determine if a part has been anodized.

Combined Coatings

Anodizing is often a preliminary step before applying additional surface finishes or coatings. This enhances adhesion and bonding for plated deposits and coatings.

Consider additional coatings such as paint, Teflon impregnation, electroplating, and other specialized processes to meet specific requirements.

Important Notes on Aluminum Anodization

Thick anodic coatings, particularly Type III, may reduce component fatigue life.

Geometric changes should be considered for parts undergoing Type II and Type III processes.

Color matching can be complex, particularly when working with different batches or vendors.

For comprehensive corrosion protection, it may be necessary to seal the pores of the anodic layer.

Abrasion resistance of Type III hard coats tends to decrease as the coating thickness exceeds 0.003 inches.

Different aluminum alloys may respond differently to the anodization process, with some being less wear-resistant under certain conditions. Consult your vendor for guidance when selecting the appropriate alloy.

Anodized Aluminum Parts Services at Sungplastic

As a metal parts manufacturer, we not only have a strong ability to produce metal parts and products, and a strong finishing and post-processing ability, in order to meet the accuracy and quality requirements, to meet the needs of customers and market.

Our surface finishing services include:

Anodizing

Plating

Teflon Coating

Powder Coating

Spray Painting

Color Matching

Pad and Silk Screen Printing

Hardening

Grinding and Polishing

Sandblasted and Brushed

Please contact us if needed.

Get a free quote and design analysis today.

We’ll reply to you within 6 working hours.

We respect your privacy.

+86 139 2927 4777 (WhatsApp, Wechat)