Vacuum Casting Process For Rapid Prototypes

To make tangible models or prototypes of goods or parts, vacuum casting process is used as a prototyping process.

It facilitates the translation of design ideas into observable, three-dimensional objects for aesthetic and practical assessment.

Vacuum casting process makes it possible to quickly iterate and improve prototypes, which streamlines the design and engineering process.

Vacuum casting process is frequently utilized as a transitional process between prototype and mass manufacturing. For low-volume manufacturing runs or initial market testing, it can be used to make a small batch of parts.

Sungplastic delves into vacuum casting process and rapid prototyping, read more about these below, if you are preparing for you prototype projects.

What is Vacuum Casting?

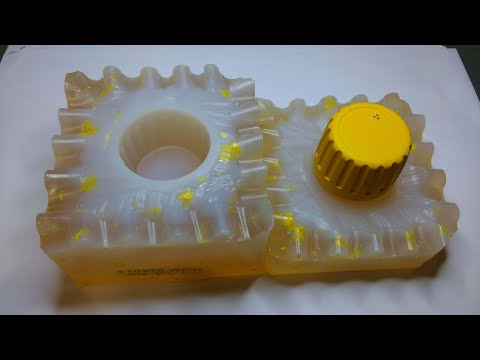

Vacuum casting, also known as polyurethane vacuum casting process or silicone rubber molding, is a manufacturing process used for producing small to medium quantities of high-quality plastic or rubber parts, primarily for prototyping and low-volume production. This process is often utilized in industries such as product development, automotive, aerospace, and consumer goods.

Material Options in Vacuum Casting Process

In the realm of vacuum casting process, the versatility and adaptability of the process shine brightly when it comes to material selection. Vacuum casting process allows manufacturers to replicate parts in a wide array of materials, matching the desired aesthetics, mechanical properties, and functionality of the original prototype. This flexibility is a key factor behind the process’s popularity in various industries, from automotive to consumer electronics.

- Polyurethane Resins

Perhaps the most commonly used material in vacuum casting process, polyurethane resins come in various formulations to mimic the properties of production-grade plastics. This versatility allows for the creation of prototypes and end-use parts with qualities ranging from rigid and impact-resistant to flexible and rubber-like. - Clear and Transparent Resins

For applications requiring optical clarity or translucent components, clear and transparent resins are a popular choice. These materials maintain exceptional clarity, making them suitable for lenses, displays, and other optical components. - Rubber-like Materials

Vacuum casting process can produce parts with rubber-like properties, such as high elasticity and excellent tear resistance. These materials find applications in gaskets, seals, grips, and cushioning components. - Fire-Resistant Resins

Some industries, like aerospace and automotive, demand materials that meet stringent fire safety standards. Specialized fire-resistant resins are available for vacuum casting process, ensuring compliance with these requirements. - High-Temperature Resins

In environments where parts must withstand elevated temperatures, high-temperature resins are indispensable. These materials can endure extreme heat without compromising their structural integrity. - Metal-Coated Parts

Vacuum casting process can also incorporate metal coatings for parts that require metallic appearances or enhanced conductivity. These coatings can be applied to the surface of the casted parts for a variety of functional and aesthetic purposes. - Color Matching

Vacuum casting process allows for precise color matching, enabling the production of parts that align with brand identity or specific design requirements. This is especially valuable for consumer products and branding-focused applications. - Overmolding

Vacuum casting process permits the use of multiple materials in a single part. This is achieved through overmolding, where different resins with varying properties are cast sequentially. Overmolding is valuable for creating parts with complex geometries or combining hard and soft materials. - Fillers and Additives

To further enhance material properties, various fillers and additives can be incorporated into the casting resins. These additives can impart characteristics such as increased stiffness, improved heat resistance, or electrical conductivity. - Custom Material Formulations

In some cases, custom material formulations can be developed to meet unique project requirements. This level of customization is a testament to the adaptability of vacuum casting.

The availability of such a wide range of materials in vacuum casting ensures that engineers and designers have the freedom to select the optimal material for each specific application, striking the right balance between aesthetics, functionality, and performance. Whether it’s prototyping, small-batch production, or creating parts with specialized properties, vacuum casting’s material options offer boundless possibilities.

The Vacuum Casting Process for Rapid Prototyping

How does vacuum casting work for rapid prototypes? There are some steps of vacuum casting process below.

Master Patterns

The vacuum casting process commences with the creation of a master pattern, essentially a prototype constructed from a robust, solid material. Typically, this stage leverages 3D printing or CNC machining or even existing parts due to their speed, absence of the need for separate tooling, and adaptability to design alterations.

Once the master patterns are crafted, meticulous preparation is imperative before replication can occur. This preparatory phase encompasses activities such as sanding, polishing, and painting to achieve the desired surface finish. In cases where multiple components must fit seamlessly in an assembly, rigorous testing and minor adjustments are made to ensure a precise, cohesive appearance.

Making Molds

Upon completion of pattern preparation, the patterns are placed within a casting box, subsequently filled with liquid silicone. After a curing period in an oven spanning several hours, the silicone solidifies, permitting the disassembly of the casting box.

The mold is then strategically opened along a predetermined seam line, and the pattern is removed, leaving behind an empty cavity that precisely mirrors the original.

Vacuum Casting

To replicate the master pattern, the mold must be resealed, this time with a feed tube leading into the cavity. Liquid urethane resin is poured into the mold, which is then placed inside a vacuum chamber.

The vacuum serves the purpose of evacuating air from the cavity, eliminating any bubbles while ensuring the resin occupies the entire volume. Subsequently, the mold is heated in an oven, leading to the curing of the resin. Upon reopening the mold, a flawless replica of the original emerges.

These represent the fundamental steps. Now, how can vacuum casting process enhance your prospects for success in your next project?

Standard Technical Specifications

Lead Time:

Typically ready in as little as 5 working days.

Accuracy:

Usually within ±0.3%.

Minimum Wall Thickness:

For optimal mold filling, a wall thickness of 0.75 mm is recommended; a minimum of 5.5 mm is advised for superior results.

Maximum Part Dimensions:

The mold size is constrained by the dimensions of the vacuum chamber and the product’s volume.

Typical Quantities:

Typically, between 15-25 parts per mold.

Key Benefits of Vacuum Casting Process for Rapid Prototypes

- Quality

Vacuum casting process yields excellent quality parts, faithfully replicating even intricate surface details from the original. Thorough preparation of master patterns is crucial. The resulting replicas can be further enhanced through painting, printing, or machining to improve both appearance and functionality. The resemblance to plastic injection-molded parts often surprises newcomers to this service. - Speed

In comparison to the weeks required for crafting mass production steel tools, parts can be prepared and delivered within days, depending on size and complexity. This can be vital when facing tight deadlines, such as preparing display models for trade shows or crowdfunding campaigns. - Versatility

A wide range of casting resins is available, reproducing the appearance, texture, and mechanical properties of standard thermoforming resins like nylon, ABS, or polyethylene. This means there’s no need to compromise functionality for the sake of speed or convenience. Additionally, different types of urethanes can be overmolded to create various surface textures and hardness levels within a single unit. - Cost-Effectiveness

Once master patterns are prepared, vacuum casting stands out as the most cost-effective means of producing high-quality replicas. Unlike plastic injection molding or pressure die casting, no substantial investment is required in creating hard tools. These savings can be redirected toward further product development or alternative design iterations. Moreover, the process consumes significantly less electricity compared to injection molding, die casting, or CNC machining, translating to cost savings for the customer.

Applications and Industries for Vacuum Casting

Vacuum casting is a versatile manufacturing process with a wide range of applications across various industries. Its ability to produce high-quality, detailed, and functional prototypes and low-volume production parts makes it a valuable tool for numerous sectors. Here are some key applications and the industries that benefit from vacuum casting.

- Product Design and Development

Consumer Products: Vacuum casting is frequently used to create prototypes of consumer goods such as electronics, household appliances, and toys.

Medical Devices: Medical equipment and devices, including surgical tools and prosthetics, are developed and tested using vacuum-cast prototypes. - Automotive Industry

Custom Parts and Components: Automotive manufacturers use vacuum casting to produce custom parts and components for vehicle design and testing.

Concept Cars: Prototyping concept cars and their intricate parts is made more accessible through vacuum casting. - Aerospace and Defense

Prototyping Aircraft Components: Engineers in the aerospace and defense sectors use vacuum casting process to create prototypes of aircraft components, ensuring precision and functionality. - Architecture and Construction

Architectural Models: Architects and designers utilize vacuum-cast architectural models to visualize and communicate their designs effectively. - Art and Sculpture

Artistic Creations: Artists and sculptors employ vacuum casting to replicate their intricate art pieces or sculptures. - Electronics and Telecommunications

Casing and Enclosures: Vacuum casting process produces custom casings and enclosures for electronic devices, ensuring a snug fit and proper functionality. - Jewelry Manufacturing

Custom Jewelry: The jewelry industry utilizes vacuum casting process to create intricate and detailed jewelry pieces, including molds for precious metal casting. - Prototyping Services

Rapid Prototyping Companies: Companies offering prototyping services use vacuum casting process to provide cost-effective and high-quality prototypes to various clients in diverse industries. - Education and Research

Educational Models: Educational institutions and research organizations use vacuum-cast models and prototypes for scientific experiments and educational purposes. - Entertainment and Film Production

Special Effects: Vacuum casting process aids in the creation of props and special effects for movies, television shows, and theatrical productions. - Consumer Electronics

Handheld Devices: Prototypes of handheld devices, including smartphones and tablets, are often produced using vacuum casting process for ergonomic testing and design validation. - Dental and Orthodontics

Dental Models: Vacuum-cast dental models and prosthetic devices are used in the dental and orthodontic fields for diagnostic and treatment planning.

Vacuum casting process’s ability to deliver high-quality, functional prototypes with fine surface details makes it an invaluable tool for innovation, design validation, and small-scale production in these and many other industries. Its cost-effectiveness, speed, and versatility continue to drive its adoption across a broad spectrum of applications.

Tips for Successful Vacuum Casting

- Precise Master Patterns

Start with meticulously crafted master patterns. The quality of your final parts depends on the accuracy and finish of these initial prototypes. - Surface Preparation

Prior to creating the silicone mold, ensure that the master pattern’s surface is smooth, polished, and free of imperfections. This step directly impacts the quality of the cast parts. - Mold Material Selection

Choose the appropriate silicone rubber for your molds. Consider factors such as flexibility, heat resistance, and the level of detail needed in the final parts. - Proper Mold Venting

Incorporate vents and channels in the mold design to allow trapped air and gases to escape during the casting process. This prevents bubbles and voids in the final parts. - Optimal Mold Temperature

Maintain consistent mold temperatures during the casting process. This ensures that the casting material flows evenly and cures correctly. - Casting Material Choice

Select casting materials that match the desired properties of the final parts. Consider factors like hardness, color, and mechanical characteristics. - Degassing the Casting Material

Before pouring the casting material, degas it in a vacuum chamber to remove air bubbles. This step enhances the clarity and quality of the final parts. - Proper Filling Technique

Pour the casting material slowly and evenly into the mold to prevent air entrapment. Use a feed tube to facilitate filling. - Appropriate Curing Time

Follow the recommended curing time and temperature specifications for the casting material. Avoid rushing this step, as it can impact part quality. - Quality Inspection

After demolding, carefully inspect each cast part for defects, such as air bubbles, voids, or imperfections. Address any issues promptly. - Post-Processing

Depending on your project’s requirements, be prepared to perform additional post-processing steps like painting, assembly, or surface treatments to achieve the desired final appearance and functionality. - Documentation

Keep detailed records of each casting job, including materials used, process parameters, and any issues encountered. This documentation aids in troubleshooting and maintaining consistency in future projects. - Iterative Improvement

Continuously refine your vacuum casting process based on lessons learned from each project. This iterative approach helps you achieve better results over time.

By following these tips and refining your vacuum casting skills, you can consistently produce high-quality parts and prototypes for your projects.

At Sungplastic, our comprehensive capabilities enable us to provide top-notch vacuum casting process solutions for rapid prototypes and end-use components. Backed by our experienced team, finishing services, and stringent quality inspection, you can obtain production-quality parts at a competitive production costs. Please contact us if needed.

Get a free quote and design analysis today.

We’ll reply to you within 6 working hours.

We respect your privacy.

+86 139 2927 4777 (WhatsApp, Wechat)